-

Address: 2, Reading Road,

Edison New Jersey, USA -

Address: 2, Reading Road,

Edison New Jersey, USA

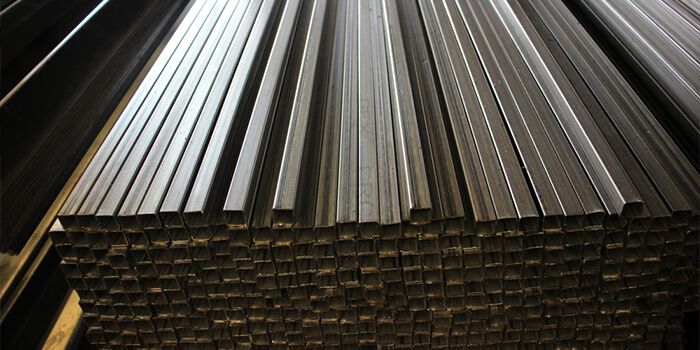

Welcome to the dedicated page for Aluminium Tubes’ Rectangular Bars. As a premier global supplier, exporter, and manufacturer with a strong focus on the USA and European markets, we provide high-quality aluminium rectangular bars, a versatile profile essential for countless structural, engineering, and architectural projects. Our bars are known for their exceptional strength-to-weight ratio, superior corrosion resistance, and excellent machinability, making them the material of choice for demanding applications worldwide.

Rectangular aluminium bars, often referred to as flat bars or flat stock, feature an elongated cross-section with flat, uniform surfaces and right-angled edges. This geometry makes them incredibly stable and ideal for load-bearing and structural applications.

We supply a comprehensive range of aluminium rectangular bar alloys to meet diverse performance requirements, with the 6000 series being the most popular for this profile.

| Alloy Grade | Primary Features | Typical Applications |

| Alloy 6061-T6 | Most popular, excellent strength, good corrosion resistance, easily welded and machined. | General engineering, structural components, automotive parts, marine fittings, fasteners, electronics. |

| Alloy 6063-T5/T52 | Good surface finish, better corrosion resistance than 6061, excellent for extrusion and forming. | Architectural trim, window and door frames, decorative elements, general-purpose applications. |

| Alloy 7075 | Extremely high strength, superior to many steels, poor weldability, fair corrosion resistance. | Aerospace structures, high-stress parts, military equipment. |

We offer a variety of tempers, including T6/T6511, which signifies the bar has been solution heat-treated and artificially aged for optimal strength.

Our high-quality rectangular bars are primarily produced using the extrusion process. This involves heating aluminum billets and forcing them through a die with the desired rectangular profile under high pressure. This method ensures precise dimensional tolerances and a uniform finish throughout the length of the bar. Further processes like stretching, heat treatment, and precision cutting complete the manufacturing to meet industry standards.

The versatility and performance of our aluminium rectangular bars make them indispensable across a wide spectrum of industries in the USA and Europe:

Custom Solutions: Beyond our extensive standard stock, Aluminium Tubes specializes in providing custom-cut lengths, specific tolerances, and various surface finishes (including anodizing and powder coating) to precisely match your project specifications. Our commitment to quality and efficient global logistics ensures timely delivery to your location, whether in the heart of Europe or anywhere in the USA.

+91 95166 18000

support@aluminiumtubes.org